Goodsky/ECE would like to introduce its new innovation which is Reflow Solderable Through-hole relay (Note: All special THR version relays are withstand reflow temperature profile following IEC 60068-2-58: 2015 as below)

Before the introduction, we will give a little explanation on the difference between SMT and THT component, and the difference of each soldering method.

Currently there are two types of electronic components, which are Surface Mount Technology (SMT) and Through-hole Technology (THT). The advantages of SMD (Surface Mount Device) component are higher components density, low initial cost of setting up for production, and faster automated assembly. But SMD component has few limitations which are not suitable for high power/ voltage part, and component level repair is more difficult. Through-hole component is ideal for product that will undergo mechanical stress, and use in high power application.

Majority of PCB board design had adapted to use SMD component because it is nothing more than lower cost and higher yield rate. However, SMD and Through-hole component require different methods of soldering production process, SMD component uses reflow soldering process, but Through-hole component uses wave soldering or hand soldering process. In the eyes of factory owner, you wish you can go through less production steps as possible. It means you will have less capital expenditure and faster production turn over rate. The key reason that Through-hole component cannot pass through reflow soldering process because the reflow soldering process use high temperature to melt solder paste, and the total reflow soldering process takes several minutes. In the result, the plastic material of Through-hole relay could melt, and it could cause electrical malfunction.

Currently majority electromechanical relays in the market are Through-hole type, but there are few manufactures that produce SMD type signal relay, its rated load is relatively small (usually less than 2 amperes). Thus, the product application is narrow.

Throughout the years of research and development in Through-hole type electromechanical relay, Goodsky/ECE has discovered several superior standard plastic materials which can sustain the hash melting temperature of reflow soldering process. Now PCB manufacturer have the choice to go through ONLY one reflow soldering process, because they no longer need additional wave or hand soldering production process. Also, there is research indicates the defect rate will be lower with reflow soldering process. Hereby we would like to clarify that most of Goodsky/ECE Through-hole relays can undergo reflow soldering process with special order for our THR version with only extra couple pennies but much more value added and cost saving. Our mission is taking our customers’ concern into our account, we want to grow together with our clients.

Special THR Relay

Optional Features: UL Class F Insulation System, Halogen Free, and IEC60335-1 Glow Wire Standard are available.

Standard THT Relay

THR relay will save your company a lot of time/extra soldering process and money!

But don’t let us tell you this, try it for yourself.

All we need to get started is for you to send us your Reflow Soldering profile and a Relay you would like us to cross.

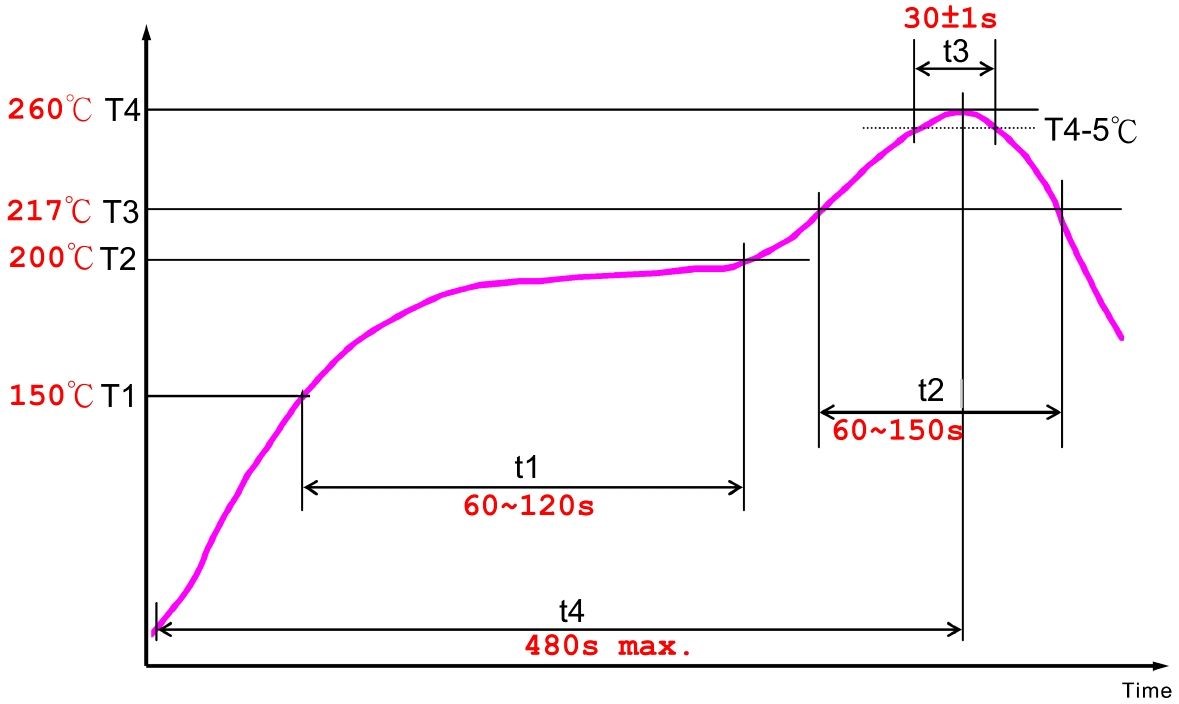

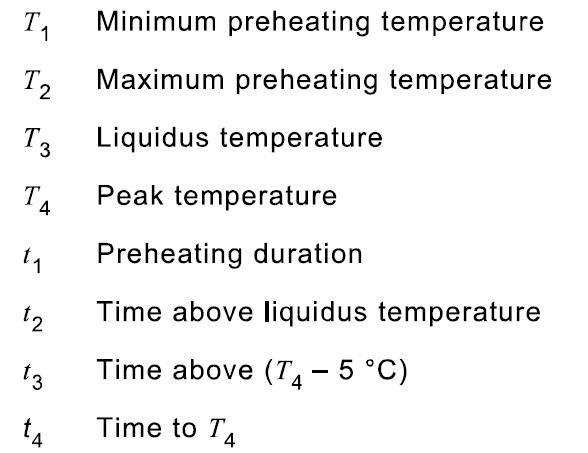

Reflow soldering condition:

As a minimum, the following parameters shown below shall be specified for reflow temperature profile.

According to IEC 60068-2-58: 2015

Note: we recommend that you confirm your actual solder conditions.